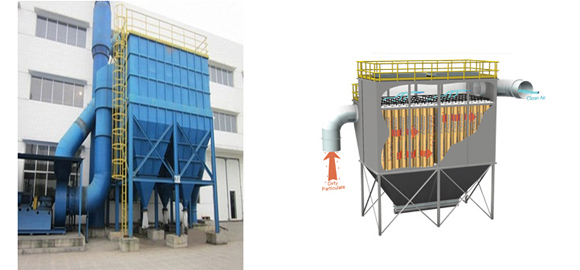

Fabric Filter Principle

Fabric filters are one of the most effective ways of removing particles from a wide range of process gases. Particle laden gas is sieved through a specially designated textile media that collects the particles of one side of the fabric. Today there are different types of fabric catering to various applications for the various temperature up to 280°C, high concentration of acid and even abrasive dust.

When an amount of the dust/particles has built upon the filter, air is send through the fabric from reverse side and caked dust falls to hoppers below

Fabric Filter Principle

Fabric Filter of High Ratio Design with a centre inlet is widelyaccepted in industrial applications around the world. The filter has proven its capacity of achieving low particulate emissions in a multitude of application.

Features

- Low first cost

- Heavy industrial design for reliability & durability

- Woven and felted fabric

- Outside collection

- On/Off line cleaning

- Panel, Modular & More compact design due to higher filter velocities

- Pulse air cleaned

- Bag and cage replacement from clean air side of the unit.

- Filter speed up to 6.0 FPM

Filter Bag Cleaning Principle of Pulse-Jet Filter

The fabric bags are cleaned by means of compressed air pulse jetting directly down through the bag opening. The compressed air expands the bag with such a strong acceleration that the dust cake on the outside are loosened and the bag later contracts.

The bags are cleaned via a tube named blast pipe. The distribution of air in short pulses is done by means of a pulse valve. The collected dust falls on a hopper located under the bags and is transported away by Rotary feeder / screw conveyor.