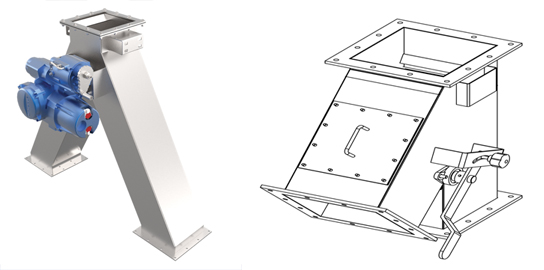

Rotary Air-lock Valves/dischargers

Available in cast as well as fabricated construction.Sizes available from 100 mm to 600 mm with squareor circular inlets.Various rotor configurations. Special valves for abrasive duty conditions.

Airlock available for pressure differential. Drop thru/off-set/blow thru designs available.

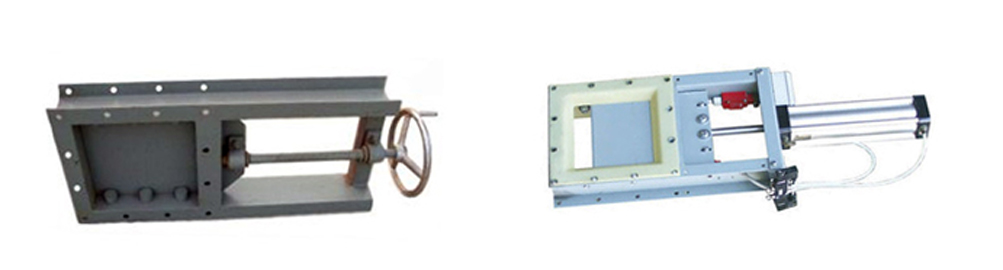

Slide Gate Valves

Available in any size,

In square/circular disc configuration,

Slide gates available in various MOC to suit product And process conditions,

Actuation by pneumatic/electric actuators

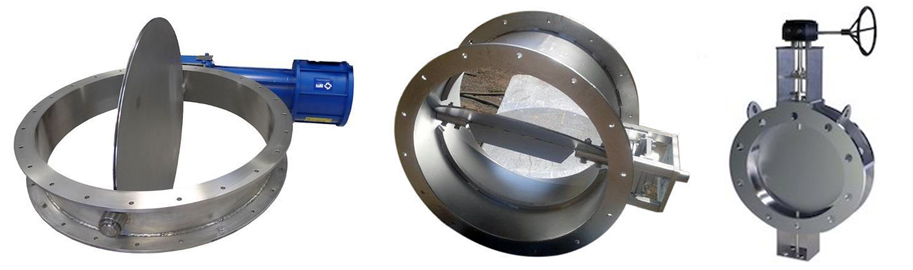

Industrial Dampers

Butterfly type dampers suitable for various diameter/temperatures.

In various MOC and for medium pressure differential. Automation by pneumatic or electric actuation.

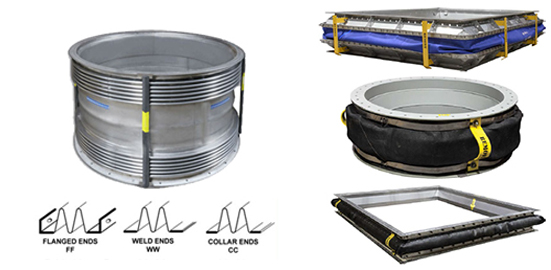

Expansion Bellows For Ducts

Available for different diameter ducts in either Circular/square or rectangular configuration.

Special MOC for higher temperatures upto 900 deg.

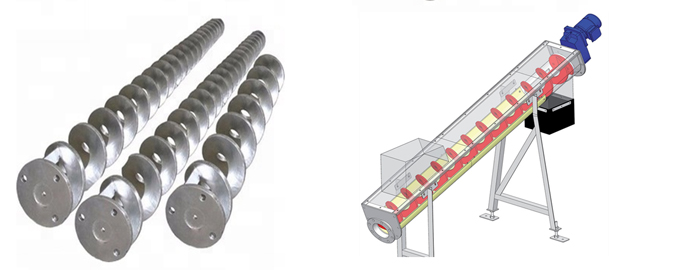

Screw Conveyors

Available from 100 mm to 500 mm sizes-single/twin/three or four shaft configuration.In various flight pitch configurations. WearResistant flights for abrasive materials.

Diverter Chutes/flow Diverters

For diverting the flow of material to 2 or 3discharge stations.

Leak proof design.

Automation by pneumatic/electric actuation.