Infrared Thermography

The Knowledge of hear patterns and associated temperatures will provide meaningful data about a process, systems, or structures. Infrared Thermograph is useful for condition monitoring to find problems in mechanical, electrical and process equipments. It is also used for quality assurance inspections.

Thermography definitely should be one of the tools that are selected for motor and rotation equipment inspection. Thermo graphic examination can help technicians use the other tools, such as vibration analysis, more effectively. If a thermal anomaly is found, then the other tools can be employed to help isolate the cause of the problem.

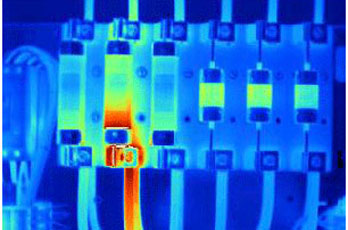

These high-resolution infrared imaging systems allow thermography to be applied to more applications than ever before, such as with mechanical systems, intricate process equipment, and printed circuit boards. Infrared thermography can detect unseen problems such as loose or deteriorated electrical; connections. Timely repair of these incipient failures can provide tremendous cost savings by avoiding unscheduled downtime.

Applications

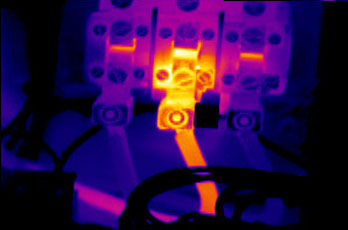

Electrical Maintenance

Poor Wiring

Bas Fuse

Electrical Motor Maintenance

Lose Connection

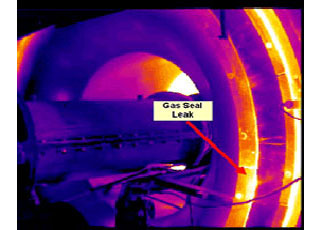

Process Thermography

Pipe Insulation Checks

Steam Leakages

Rotating Kiln Thermography

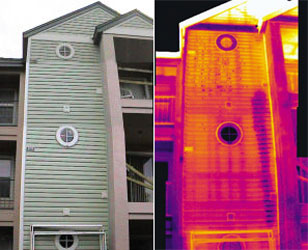

Building Thermography

Moisture Detection in Building

Insulation Check

Clinical Thermography

Breast Cancer Detection